The RV World’s Forever FAQS

Getty Images

Times change—but some of the key puzzles facing RVers do not. Our longtime how-to columnist plays the greatest hits.

Ken Freund has been responding to readers’ questions about RVs for many years. Across this long run, some subjects have proven perennial. Here, he takes on five key topics:

Battery charging during storage

Winterization

Roof maintenance

Slide-out maintenance

Lithium battery conversion

Q: Why do my RV batteries keep going dead during storage?

A: Batteries slowly self-discharge over time, even if they are not connected to any load. A rough rule of thumb for conventional batteries is 1 percent per day, although that varies considerably between batteries, temperatures, etc. Lithium batteries may discharge more slowly, around 3 percent per month.

However, the main cause of battery discharge on modern vehicles, including RVs, is parasitic current draws. These are found all over these vehicles, including: electronic circuit boards used in refrigerators; propane; carbon monoxide and smoke alarms; clocks; radios; et cetera.

Most of these draws aren’t large individually. Taken together, though, they can drain a battery in a few days or weeks.

Lead-acid batteries that are left discharged can become sulfated, which reduces their capacity and may even ruin them. Lithium batteries should also not be left fully discharged. Therefore, you need a way to keep your batteries charged even when you are not using your RV. Many newer RVs have “smart” charging features built into their power converters or inverters. If you plug in the RV during storage, a smart charger may maintain a proper charge. However, many power converters just have “dumb” battery charging circuitry, which keeps dumping a fixed amount of charging power into the batteries even after they are fully charged. This will overcharge and damage batteries.

So—you need to verify what type of charger you have, and if it is compatible with the type of batteries you use (lead-acid wet cells, AGM, lithium) and set properly. This information is included in the instruction manuals that come with the RV and the components also are typically labeled.

If your RV does not have a built-in smart charging feature, you can use an aftermarket smart maintenance charger (such as products from Battery Tender). Some chargers are designed to charge multiple batteries, a handy feature for RVs with several.

Before and occasionally during storage, be sure to check the electrolyte level on wet cell batteries and add distilled water as needed. Fully charged wet-cell batteries are also protected from freezing. Lithium batteries should be kept warm before charging. It’s best to keep them in a garage in cold weather.

Q: What do I need to do to winterize?

A: To start with the most fundamental factor, it depends on what part of the country you are in and the local climate. If you are in an area like South Florida, where it normally doesn’t freeze, there is little that needs to be done. However, in regions that have regular freezing weather, it’s important to thoroughly prepare your RV. Always consult your RV owner's manual for specific instructions on winterizing your particular model, but here are some priorities:.

Dump the gray-water tank and black-water tank completely. Put some liquid toilet tank chemical in through the toilet to control odors.

Open low-point drains to ensure all freshwater is drained.

Remove the drain plug on the bottom of the water heater to empty any remaining water.

Bypass the water heater with the bypass valve located by your water heater (or install one if not equipped) to prevent RV antifreeze from filling the tank unnecessarily.

Remove and drain any water filters or softeners and reconnect the lines before pumping RV antifreeze through the system.

Pour two or three gallons of special non-toxic RV antifreeze into the fresh-water tank. Run the water pump and open faucets one at a time until pinkish water comes out.

Flush the toilet(s) to push antifreeze into the valve and black-water tank.

Alternatively, you can use compressed air to blow out the lines. This video may help.

Refer to manufacturer’s instructions for winterizing appliances such as ice makers, washing machines and dishwashers.

Disconnect and store batteries in a dry place such as a garage. If this is not practical, leave batteries in place, but disconnected. In any case, keep batteries charged using a maintenance charger designed for storage and the type of batteries being charged.

Take measures for rodent protection, including blocking off entry points and using poison baits, etc.

If storing outside, it’s best to apply a protective wax, and/or cover the RV exterior.

If you are unsure about any aspect of winterizing your RV, consider having a professional do it.

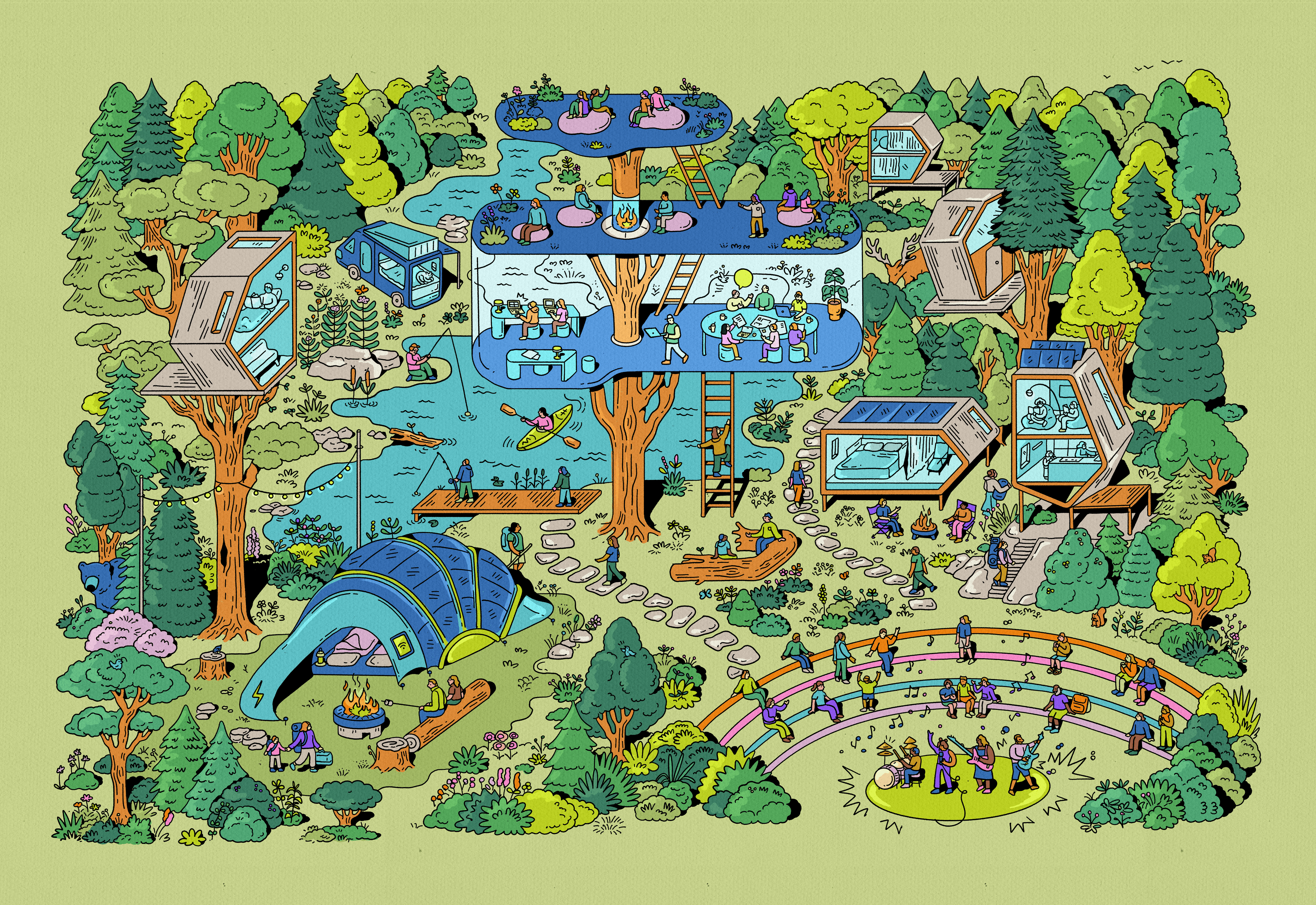

THE CAMPGROUND OF THE FUTURE

We’ve reimagined camping for the year 2050.

Q: What needs to be done for roof maintenance?

A: RVs feature various materials on their roofs: EPDM rubber, TPO, fiberglass, steel or aluminum. They all need to be cleaned and inspected. Membane roofs require more regular inspections and maintenance—see below for more on these.

As a basic process, clean and then inspect the roof for damage. Remove leaves, debris and mold, washing thoroughly. Use RV-specific products designed for your type of roof. Remove any deteriorated sealer and reseal with an RV-specific sealer such as Dicor lap sealant. Do not use household caulking, RTV silicone or petroleum-based products such as tar, etc.

Check for signs of leaks and address them promptly, especially around seams, vents and air conditioners. If you find any holes or tears, patch them immediately using RV roof repair tape or sealant. My favorite way to repair cuts and tears is with specialized roofing repair tape such as Eternabond.

Most RV roofs are membrane roofs, also called rubber roofs, which consist of a synthetic rubber membrane over plywood. The two main types of membranes used for RV roofs are EPDM and TPO. EPDM stands for ethylene propylene diene monomer, and it’s been used on RVs for decades. EPDM is manufactured in a black color, and then a white coating is applied for sunlight reflection. TPO stands for thermoplastic polyolefin. It’s newer than EPDM, and has the same color throughout the membrane.

With fiberglass and membrane roof material, consider applying a protective coating to extend its life and protect against UV damage. Applying protectant on a fiberglass roof can slow oxidation, which, over time, makes the gelcoat lose its shine. Metal roofs in good condition don’t require anything else at this point, but it’s best to wax them.

Climbing on an RV roof can be dangerous. If you are unsure about doing it yourself, have an RV shop do the work. Do not put off proper care, as this could result in expensive water intrusion and structural damage.

Q: What needs to be done to maintain slide-out rooms?

A: Regularly check the seals for dryness, damage or moisture. You can use a ladder or the roof of your RV to examine the seals at the top of the slideout room(s). Also check the seals that run down the sides of the slideout and the seal beneath the slide room.

Keep the slideout clean, especially the roof. Special lubricant for seals is available from RV dealers.

You can use a slide-out awning to protect the roof from debris. Some models come with them from the factory. Wax the slideout roof every spring and fall. Waxing assists water runoff and helps prevent snow and ice from bonding to the surface. If you don't have an awning, clean the roof before retracting the slide-out room.

Keep your 12-volt DC battery bank maintained, including clean tight connections, to provide sufficient power for slide operation. Never leave your slide partially open or partially closed. Look for abnormal wear patterns on the interior floor of the slide out. Listen for any unusual sounds when moving the slide out.

Slideout mechanisms come in several distinct types. There are cable-driven systems, hydraulic-ram systems and gear-driven track systems. All use electric motors and controls. Read the instructions that come with your coach. Familiarize yourself with the manual retraction procedures for your specific model.

Clean, inspect and lubricate the slideout mechanism(s) at least twice a year. The type of lubricant required depends on your RVs type of slide system; use the factory recommended type. Look for leakage and check hydraulic fluid levels regularly on mechanisms that use hydraulics. If unsure about doing any part of it yourself, consult your favorite RV shop or dealer for maintenance and service of slide-out mechanisms.

Q: What do I need to do to switch to lithium batteries?

A: Lithium battery conversions have become very popular in recent years, partially due to the increased use of solar panels, along with declining prices and better performance. Most RVs come with standard lead-acid batteries, which are heavy and limited in capacity. Lead-acid batteries should not be discharged below 50 percent, as this can significantly reduce their service life. In contrast, lithium RV batteries can be discharged about 80 percent without significantly affecting their lifecycle, so you get more power from a given size battery. Lithium batteries are lighter, more efficient and have a higher energy density than lead-acid batteries, making them an ideal choice for RVs.

They also have significantly different charging needs. To change your RV from lead-acid to lithium coach batteries, you'll need to determine if your battery charging system (inverter or converter/charger) is compatible with lithium batteries. This may require an upgrade or modification to properly charge the new lithium batteries. You might have to adjust voltage settings. Newer RVs typically have a lithium setting; with older models you may need to upgrade your converter/charger to one specifically designed to work with lithium batteries.

Motorhomes and tow vehicles provide charging voltage to the coach batteries from the engine alternator when the engine is running.

Charging lithium batteries directly from an engine’s alternator without proper current regulation can be unsafe. Lithium batteries current draw can exceed the alternator's maximum output, which may cause the alternator to overheat and burn out. To adapt the charging voltage from the engine alternator for a 25-Amp charger to be suitable for a 100 Amp-hour (Ah)-rated coach battery, you want a capacity of about 25 percent of the battery pack’s Ah rating.

Another item to use is a Lithium Ion Battery Isolation Manager (Li-BIM), which prevents alternator overheating by cycling the charge. When the engine is running, the Li-BIM will cycle on and off to allow the alternator to cool down.

Lithium iron phosphate (LiFePO4) batteries are designed for, and work well in RV use. Determine the capacity of lithium batteries needed based on your RV's power consumption and how long you plan to be off the grid between charges. Typical installations range from 200 to 400 Ah.

An important feature to look for is a battery management system (BMS) that’s built into the battery, which protects it from overcharging and overheating. Look for lithium batteries that come with a built-in BMS, which should be considered essential.

Double-check your wiring for proper polarity (+ & -) and ensure it’s a heavy enough gauge for the new battery capacity. Lithium batteries also require a different type of charge-level monitor than lead-acid batteries; verify that yours is compatible. If you're not comfortable with electrical work, consider having a professional install your lithium batteries.

Let's Rally

The Winter 2024 Digital Issue